FEATURES & OPTIONS

STAINLESS/SANITARY/FOOD GRADE FINISHES

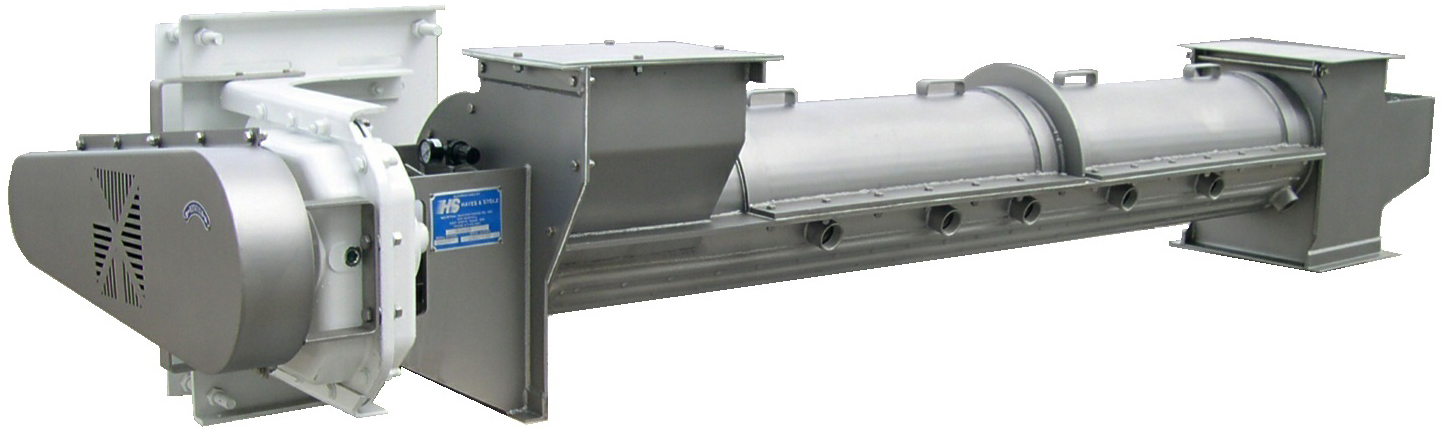

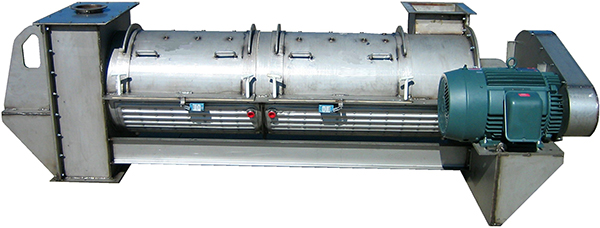

With experience SINCE 1945 in commercial and industrial blending, Hayes & Stolz has acquired and developed the skills necessary to manufacture Continuous Blenders with the appropriate finish for the intended application. Our DA (Pug Mill), SA, L56 and E-Z Blenders can be designed and manufactured for stainless/sanitary/food grade applications.

The following descriptions for standard finishes are from the “Hayes & Stolz Procedures for the Manufacture and Finishing of Stainless Steel Equipment“. For a detailed description of each standard finish see the Technical Documents section of this web-site. While these procedures address the standards adopted by Hayes & Stolz, they are not intended to limit our ability or willingness to provide a custom finish to a customer’s own specification.

ULTRA-SANITARY STAINLESS STEEL (USSS):

Used primarily when “sanitary construction” is specified for food, chemical and pharmaceutical industries requiring stainless steel product contact surfaces and a finish with no cracks or crevices and a high degree of interior polish. Interior is polished to 120 grit final finish.

SANITARY STAINLESS STEEL (SSS)

Used primarily when “sanitary construction” is specified for food, chemical and pharmaceutical industries requiring stainless steel product contact surfaces and a finish with no cracks or crevices, but not requiring the highest degree of interior polish. Interior is polished to 80 grit final finish.

STAINLESS STEEL COMMERCIAL (SSC II)

Used primarily when “stainless steel construction” is specified. Commercial design shall be the same as for standard carbon steel units for non-sanitary applications. Interior and exterior finish shall be as-fabricated. The exterior of SSC-II equipment will not be painted.

STAINLESS STEEL COMMERCIAL (SSC I)

Used primarily when “stainless steel product contact surfaces” is specified. Commercial design shall be the same as for standard carbon steel units for non-sanitary applications. Interior and exterior finish shall be as-fabricated. The exterior of SSC-I equipment will be painted.

SPECIAL DUTY APPLICATIONS

In addition to the stainless/sanitary/food grade applications Hayes & Stolz offers options for several special duty applications:

For applications involving abrasive products, H&S Continuous Blenders can be designed to incorporate abrasion-resistant paddles and critical wear areas. The paddle tips (and leading edges of ribbons on E-Z Blenders) can also be hard-faced with a welded overlay.

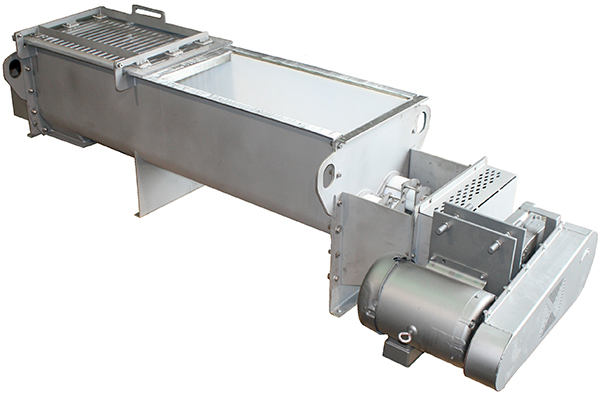

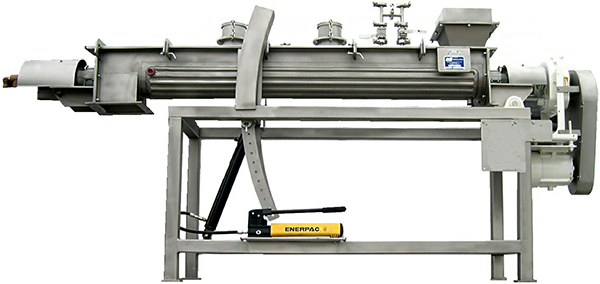

E-Z Blenders used to blend “sticky” ingredients can be furnished with UHMW liners on the u-trough housing, shaft, cross-arms and paddle faces for easier release. (Illustrated in photo to the left.)

COVER OPTIONS

For u-trough style blenders (DA, SA and E-Z Blenders) covers are provided for protection required by OSHA from the moving parts and for a means to contain/control dust from the blending process. They can also be designed to include ports for dry and/or liquid ingredient addition, dust pick-up ports, and access for inspection and cleaning. H&S blender covers can be custom designed to allow for the best integration with the customer’s operation.

LIQUID ADDITION

For processes that require the addition of liquids, Hayes & Stolz can provide liquid injectors, manifolds and/or spray nozzles. The type and location for liquid addition will be determined for optimum performance for the application.

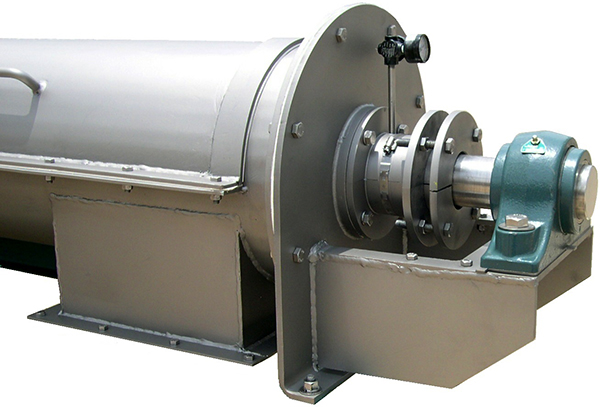

SHAFT SEALS

Hayes & Stolz offers a variety of seal options for the main shaft penetrations through the end plates. The selection of seals that are properly suited for the blending application is important in order to minimize leakage and reduce premature shaft wear that results in expensive repairs and down time.

MISCELLANEOUS OPTIONS

Hayes & Stolz has extensive knowledge of numerous blending applications for many industries and is uniquely qualified to recommend the right features and options to enhance the performance of our blenders and improve blending productivity.

CUSTOM DESIGNS

Hayes & Stolz is not just an equipment manufacturer. We Deliver Solutions. Contact a qualified Hayes & Stolz Sales Engineer to discuss custom designs of Hayes & Stolz Blenders to meet your specific needs.