FEATURES & OPTIONS

Features:

Bucket Elevators are designed for weather and dust tight operation.

Bucket styles and operating speeds for bucket elevators are selected to match the material characteristics of the product being elevated.

Options:

– Access ladders, and platforms are available. Fall Protection Required (by others) per OSHA 1910.28.

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.28

Optional 1000 lb. capacity jib booms can be supplied for mounting to the head section to be used to hoist maintenance items.

For applications covered by NFPA 72, optional explosion relief panels can be installed in the head section and casing sections. NFPA compliant motions switches, bearing temperature sensors, belt alignment sensors and total elevator monitoring systems can be also be supplied.

LINERS

For abrasive applications, all models of Hayes & Stolz Bucket Elevators can be furnished with abrasion resistant liners at impact points and wear areas. Standard lining materials are 1/4” polyurethane, 3/8” ceramic-chip-embedded polyurethane or 1/4″ ceramic hex tiles. Wear areas can also be manufactured of A/R (abrasion resistant) steel for prolonged life.

For higher capacities, Hayes & Stolz can design the bucket elevator to accommodate multiple rows of buckets on a single belt.

During maintenance operations, often the bucket elevator needs to be advanced only a short distance. Inching drives allow for moving the belt and buckets at a very low speed.

Hayes & Stolz also offers optional chain and sprocket type bucket elevators with heavy duty chains and hardened sprockets. Buckets are attached via standard chain attachments.

CONSTRUCTION MATERIALS AND FINISHES

Hayes & Stolz Bucket Elevators can be furnished of mild steel, stainless steel or galvanized construction.

Mild steel units, manufactured entirely of mild steel, will have the complete exterior painted with an industrial polyurethane topcoat (standard color is SW Pillar White) over rust inhibitive primer.

Stainless steel units provide stainless steel product contact surfaces. Exterior stainless steel can be unpainted or painted with an industrial polyurethane topcoat (standard color is SW Pillar White) over stainless-compatible primer.

When galvanized construction is specified head and boot sections will be of mild steel construction and hot-dip galvanized per ASTM A123 specifications prior to assembly. Casing sections are fabricated of galvanized sheet with zinc rich “cold patch” paint over the welds to ASTM A780.

A gland type seal can be added to the boot section to provide additional dust tight measures.

WING PULLEYS

To minimize product build-up, the standard crown faced boot pulley can be substituted with an optional wing type pulley with or without a spiral face.

The screw type take-up assembly for standard boots can be operated by optional air cylinder or a weight box to maintain constant belt/chain tension.

The standard air cylinder take-up assembly for 71-A boots can be substituted with a weight box to maintain constant belt/chain tension. A screw type take-up can be used, but will require manual adjustment to maintain tension.

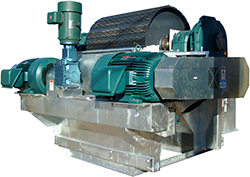

Internal Gravity Take-ups (shown at the left) or Head Take-ups for smaller legs can be provided.

As an option for the standard unitized casing design, independent “up” and “down” casings can be furnished with leg ties that join them at installation. The non-unitized casing sections can be nested better for shipping purposes, but require additional time and attention during installation.

An option for the double casing is a box casing enclosing both the “up” and “down” sides of the belt/chain.

Hayes & Stolz is not just an equipment manufacturer. We Deliver Solutions. Contact a qualified Hayes & Stolz Sales Engineer to discuss custom designs of Hayes & Stolz Bucket Elevators to meet your specific needs.